When we explore home showrooms or design magazines, beautifully crafted cabinets often stand out. But have you ever wondered how they’re made? From design to installation, every step reflects skilled craftsmanship and advanced technology. Understanding this process helps you appreciate their quality and make smarter choices for your home.

How Are Cabinets Made? A Step-by-Step Guide to Precision and Craftsmanship

Creating cabinets involves a detailed and precise process. From the initial design to the final storage, each step ensures quality and durability. Here’s a breakdown of the cabinet-making process:

Step 1: Designing the Perfect Layout

The cabinet manufacturing process starts with meticulous planning and design. Using advanced CAD software, designers create detailed layouts that determine the size, style, and structure of the cabinets. Once finalized, these CAD drawings are handed off to the production team, where every specification is carefully analyzed to set clear parameters for production.

After the design phase, the focus shifts to materials preparation. High-quality cabinets rely on strong and durable materials, such as veneer wood, particle board, and MDF. These materials are chosen for their resistance to temperature changes, pressure, and wear. Composite wood is also widely used for its affordability and compliance with modern environmental standards.

The cabinet manufacturing process starts with precise CAD designs, detailing cabinet dimensions, panel types, hardware needs, and screw placements. These plans guide the production process, ensuring accuracy. Materials like veneer wood, particle board, and MDF are selected for their durability and resistance to wear.

Composite wood, paired with low-formaldehyde adhesives, offers affordability and eco-friendliness. Adhering to strict E1 Standard (≤1.5mg/L) emissions, PA cabinets combine thoughtful design and sustainable materials to create high-quality, environmentally friendly cabinets.

Step 2: Cutting the Materials

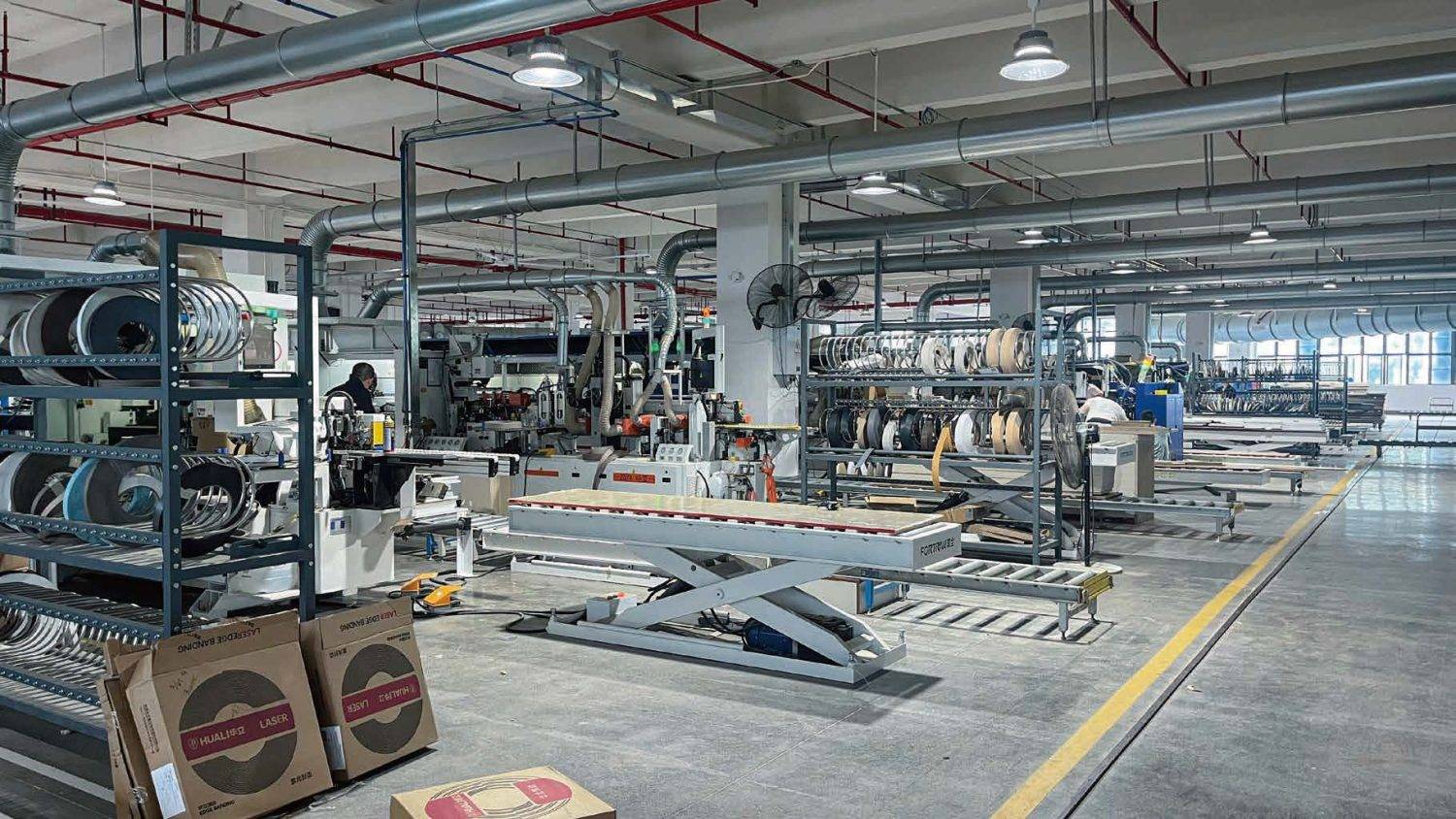

Ever wonder how cabinets get their clean, sharp edges? Automated cutting machines handle this step with precision. They cut materials like MDF or plywood into the required shapes and sizes based on the design. No manual guesswork here—automation reduces errors and speeds up the process.

Step 3: Grooving for Perfect Fits

Now comes the grooving step. First, grooves are added to the panels to create slots for the back panels and drawer bottoms. This way, the assembly process ensures a seamless fit. Moreover, precision is critical here because even a tiny mistake could cause the parts to misalign.

Step 4: Edge Banding for a Smooth Finish

After cutting and grooving, raw panel edges need some attention. Edge banding covers these edges, protecting them from moisture and giving the cabinet a polished look. Materials like PVC or veneer are commonly used, ensuring durability and aesthetics.

Step 5: Drilling and Assembly

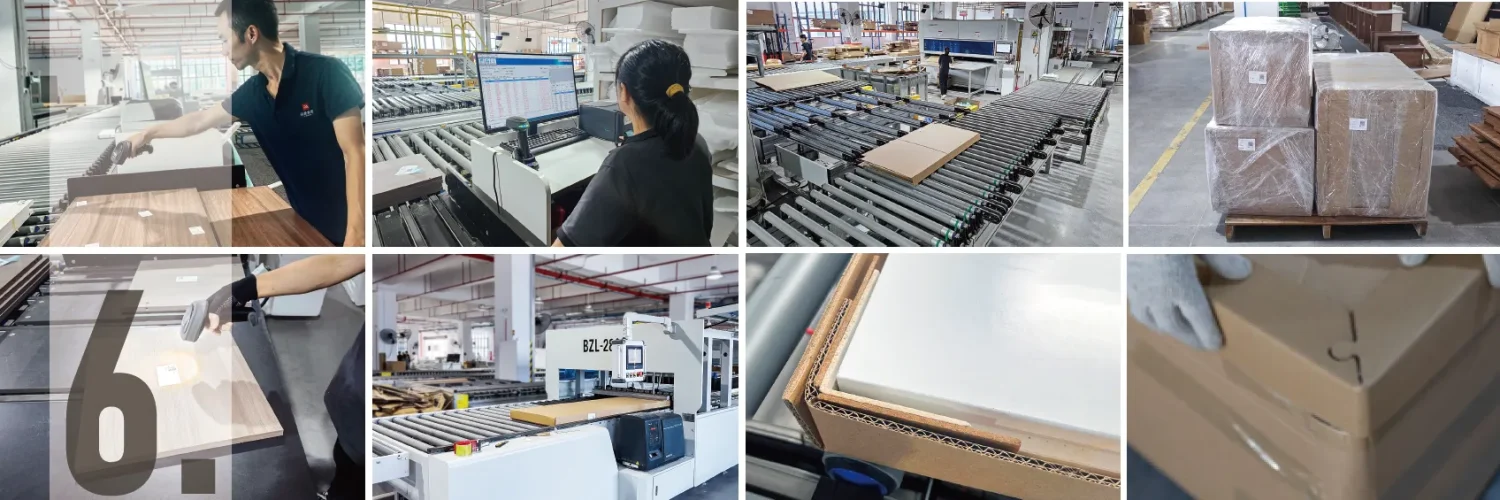

Next, it’s time to drill the holes. Precision is everything—holes are drilled at exact locations to accommodate screws, hinges, and other hardware. With pre-drilled panels, assembly becomes a breeze, creating sturdy cabinets ready for use.

Step 6: Rigorous Quality Checks

No one wants a cabinet with flaws, right? That’s why every panel and joint is inspected. Measurements, finishes, and hardware placements are double-checked to ensure everything meets the highest standards. If it doesn’t pass, it doesn’t move forward.

Step 7: Packaging and Storage

After the cabinets pass inspection, workers carefully package them. First, they label and scan each component to ensure nothing is missing. Then, they use high-quality packaging materials to protect the cabinets during transportation, keeping them in perfect condition. Finally, workers store the packaged products in an organized warehouse, ensuring they are ready for delivery. This process minimizes errors and guarantees safe handling from start to finish.

What Materials Are Used to Make Cabinets?

How are cabinets made? materials play a huge role in the final product’s quality and durability. Let’s look at the most common options and what makes them unique:

| Material (English) | Features | Advantages | Disadvantages | Common Uses |

|---|---|---|---|---|

| Solid Wood | Made from natural timber, offers natural texture, beauty, and eco-friendliness. | Durable, strong, natural aesthetics, can be polished and shaped. | Expensive, prone to cracking and warping in varying temperatures, requires maintenance. | High-end cabinets, furniture bases, visible panels. |

| Plywood | Made by bonding multiple layers of wood veneers under heat and pressure. | High strength, durable, warp-resistant, eco-friendly options available. | Limited to flat surfaces, cannot be shaped or curved. | Cabinet doors, shelves, and structural panels. |

| Particle Board | Composed of wood chips and resin, pressed under high temperature and pressure. | Economical, lightweight, easy to process, cost-effective. | Less durable compared to solid wood and plywood, prone to edge chipping. | Budget cabinets, simple furniture structures. |

| Medium Density Fiberboard (MDF) | Made from wood fibers mixed with resin and pressed into sheets. | Smooth surface, easy to paint, uniform texture, affordable. | Susceptible to water damage, less durable, can warp under extreme conditions. | Painted cabinets, furniture components, and decorative panels. |

Choosing the Right Material

- Durability Matters: If you want cabinets that last, plywood is the go-to for strength and resistance to warping.

- Budget-Friendly Options: MDF is a great choice when cost is a priority, but it’s not ideal for damp areas.

- Eco-Friendly Choices: Composite wood is increasingly popular due to its adherence to modern environmental standards, like E1 or E0 certifications.

Each material has its pros and cons, so the “best” depends on your needs, budget, and style. The key is knowing what works for your space and lifestyle.

What Tools Are Used in Cabinet Manufacturing?

Have you ever wondered about the tools behind it? The right equipment makes all the difference in precision and quality. Here’s what’s commonly used:

What Are the Key Tools in Cabinet Production?

| Tool | Purpose | Advantages |

|---|---|---|

| CNC Machines | Used for precise cutting and drilling of materials. | Ensures exact measurements, reduces waste, and speeds up production. |

| Edge Banding Machines | Seals panel edges to improve durability and aesthetics. | Provides smooth, clean edges and protects against moisture and wear. |

| Vacuum Press Machines | Applies surface finishes, like veneers or laminates, to panels. | Enhances the cabinet's visual appeal and adds a layer of protection. |

So, what’s the secret? It’s all about blending advanced tools with skilled hands. That’s how you get cabinets that are not just beautiful, but built to last.

What Determines the Quality of Cabinets?

Materials Matter

The foundation of a good cabinet lies in its materials. Durable options like solid wood, MDF, and plywood ensure strength and longevity. Eco-friendly materials that meet strict standards, like E0, are especially important for households prioritizing health and sustainability.

Hardware Makes a Difference

Think of hinges, handles, and slides as the backbone of a cabinet. High-quality hardware, such as soft-close hinges and heavy-duty slides, ensures smooth operation and long-term functionality. Cheap alternatives might save money initially but can lead to wear and tear over time.

Precision in Craftsmanship

Accurate cutting, smooth edge banding, and well-placed drilling ensure a perfect fit during assembly. Any errors in these steps can lead to misalignment and reduced durability.

FAQ

Common materials include solid wood, plywood, particle board, and MDF. Each material has unique advantages, such as durability, affordability, or eco-friendliness.

Look for durable materials like plywood, high-quality hardware such as soft-close hinges, and precise craftsmanship. Choosing a reliable manufacturer also guarantees consistent quality.