Whether you are an architect looking to inject a unique style into a building project, a contractor looking for a cost-effective solution, or a window dealer expanding its product line, custom windows are always a worthy investment. Not only can they meet personalized building needs, but they can also enhance the overall value in scenarios such as school projects, hotels, and villa developments.

Unlike ready-made windows, custom windows offer more flexible size, design, and functional options, which can significantly optimize building performance while improving the appearance of the building.However, the cost of custom windows is often one of the most concerned issues in corporate procurement and decision-making.

Today, we will comprehensively compare the cost differences between custom windows and ready-made windows and mass-produced windows, and explore in depth how to optimize the procurement process, reduce unit costs, and obtain higher returns on investment through cooperation with window manufacturers.

How Much Does Custom Window Cost Compared to Standard Window?

This is an unavoidable fact: customized windows are indeed more expensive than the standard counterparts.

This price difference is due to several factors, which we’ll explore shortly. However, it’s crucial not to focus solely on the initial cost without considering the overall value and benefits that custom windows offer.

On average, the national cost of custom windows range from $500 to $2,500 per window, depending on materials, size, and design complexity. In contrast, standard double-hung windows typically cost between $300 and $700 per window, including installation.

Due to the wide variety of custom window types, sizes, and designs, it’s difficult to provide a universal cost estimate. Labor fees and material costs can vary significantly depending on the complexity of the customization.

In general, simpler customizations or straightforward designs will result in lower costs. On the other hand, more intricate or popular window designs that require premium materials and higher craftsmanship may push the price higher.

Why are Custom Windows More Expensive?

According to window price surveys, custom windows prices are generally more than 25% more expensive than standard windows.

Why are custom windows so much more expensive than existing windows? Shouldn’t their manufacturing process be similar?

In fact, this is not the case.

There are several reasons why custom window cost is more expensive than standard window. Here are the key points:

1. Changes in Production Processes

When producing ready-made standard windows, window manufacturers usually use an efficient mass production system. The entire production process has been optimized to the highest efficiency, and all resources, including workers, equipment and materials, perform tasks repeatedly in a fixed pattern, thereby achieving fast production and high output.

However, when it comes to customized windows, the highly optimized process will be changed:

Production line adjustment: In order to meet customized needs, window manufacturers need to suspend existing assembly line production, reconfigure equipment, or even open a dedicated small-batch production line.

Capacity impact: Custom window orders often require more complex craftsmanship or designs, such as irregular shapes or large-size windows (12×60 windows or large floor-to-ceiling windows), which often require additional manual processing or require precise resetting of the machine. This means that workers and machines need more time to complete a window and cannot quickly switch to the next order, resulting in a significant reduction in overall production efficiency.

The loss of production efficiency needs to be compensated by price markups to ensure that window factories can both meet custom order windows needs and maintain overall profitability.

2. More Labor and Work Involvement

Custom windows are not simply a modification of pre-existing window designs; they require additional design and production processes, which differ significantly from standardized manufacturing. Custom orders often demand more resources, including:

Unique Design: Designers need to work closely with clients, often going through multiple iterations to create a new and fully customized design from scratch. Unlike standardized templates, this process increases the workload during the design phase.

Exclusive Production Molds: To manufacture a limited batch of custom windows, manufacturers may need to create specialized molds or adjust existing equipment. These one-off molds cannot be reused for other projects, making the cost per unit significantly higher compared to mass production.

The extra design and production steps substantially increase both labor and time costs, naturally leading to higher prices for custom windows.

3. Challenges in Material Procurement

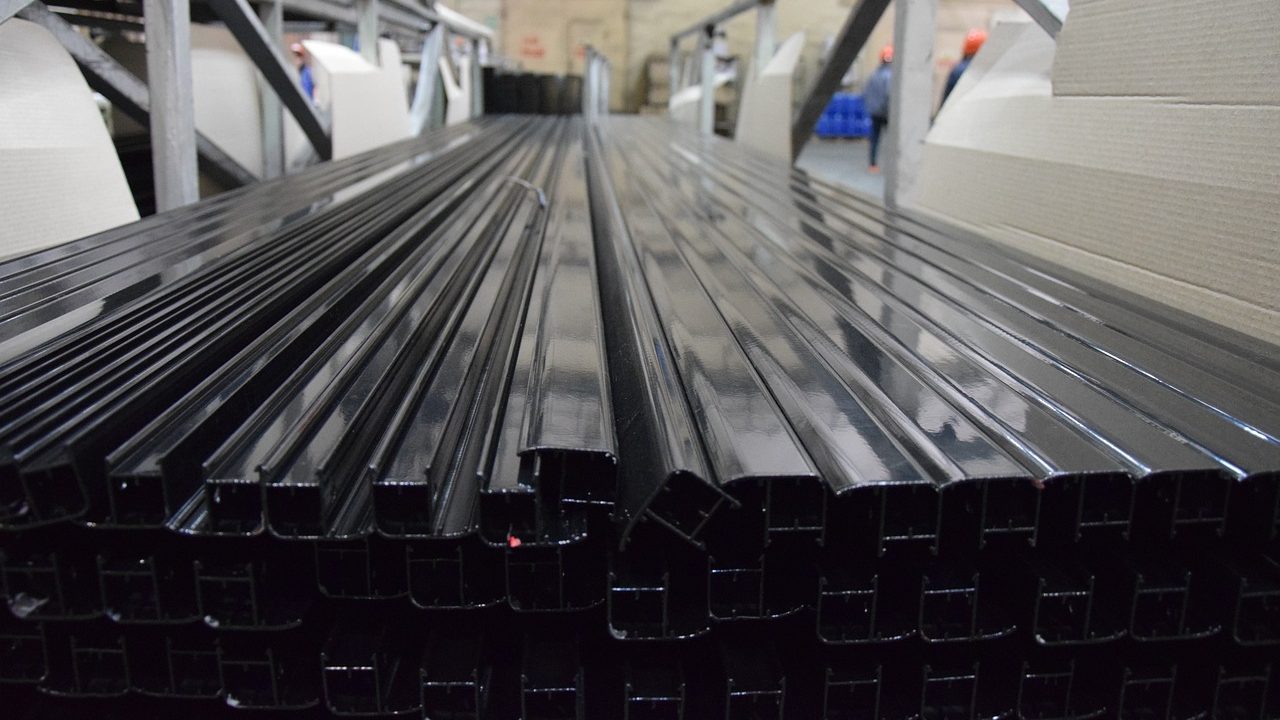

The design of custom windows often requires the use of special materials, such as fluorocarbon spray, glass, or unique aluminum window frames, which are usually not within the manufacturer’s regular inventory.

One-time procurement: In order to meet order requirements, manufacturers may need to purchase rare materials separately from suppliers. These materials are usually more expensive and may only be applicable to specific orders and cannot be reused.

Inventory waste: If the order volume of custom windows is small, unused materials may be idle, ultimately increasing inventory management and waste costs. For example, if only a portion of the expensive walnut frame purchased for a high-end project is used, the remaining wood is likely to be unavailable for other orders.

These additional material procurement costs and potential waste are directly reflected in the price of custom windows, pushing up the overall cost.

The loss of production efficiency needs to be compensated by price markups to ensure that window factories can both meet custom order windows needs and maintain overall profitability.

4. Higher Technical and Craftsmanship Demands

Custom windows frequently require skilled labor and advanced techniques to achieve their unique designs and functionalities. This added complexity primarily involves:

Distinctive Shapes: Arched, curved, or oversized windows require higher precision in cutting, assembly, and finishing processes. These tasks often exceed the capabilities of automated systems and necessitate skilled manual craftsmanship.

Functional Requirements: Windows with specialized features, such as soundproofing, fire resistance, or energy efficiency, demand advanced testing, calibration, and technical expertise. These features not only require premium materials but also necessitate highly trained teams to ensure quality.

Such advanced craftsmanship and technical requirements enhance the overall quality of custom windows but also significantly increase production costs, especially for orders requiring high levels of accuracy and expertise.

How to Reduce Budget with Custom Window?

Whether you are an architect pursuing unique designs, a contractor coordinating complex projects, or a window dealer looking for a high-quality supply chain, meeting the needs and staying within the budget is always the core goal in project execution.

Now that you understand the reasons for the price increase of custom windows, let’s learn how to optimize procurement decisions, reduce the cost of purchasing custom windows, and achieve higher cost-effectiveness within a limited budget.

1. Partner with a Reliable Window Manufacturer

Choosing an experienced and trustworthy window manufacturer or supplier is key to reducing risks and costs. For example, PA Window has 17 years of export experience, serving major clients such as designers, builders, and real estate developers. PA Window has successfully delivered over 42,000 overseas projects, including large-scale buildings like hotels, schools, apartments, and villas, showcasing its ability to handle complex projects.

PA Window’s factory is equipped with 10 Industry 4.0 automated production lines, which significantly enhance the efficiency of producing both custom and standard windows. This ensures timely delivery, giving you peace of mind when partnering with PA Window.

2. Lower Unit Prices with Bulk Purchases

For projects requiring a large number of windows, bulk purchasing is an effective way to reduce unit costs. PA Window offers attractive long-term agreements for high-volume orders. When order quantities or amounts reach specific thresholds, PA enters long-term contracts with clients, providing significant discounts.

Currently, over 500 villa developers, builders, and wholesale window dealers have established long-term partnerships with PA Window. These agreements not only secure competitive pricing but also ensure a stable and reliable supply chain for ongoing projects.

3. Choose Cost-Effective Materials

Not all projects require high-end materials like hardwood or triple-glazed glass. Selecting more economical yet functional materials based on project needs can greatly reduce costs.

For instance, a real estate developer in Melbourne, Australia, initially planned to use steel-framed folding windows but switched to aluminum folding windows provided by PA Window. This decision lowered the entire project’s budget by 20% while maintaining high-quality standards.

PA Window’s expert team can recommend the best materials for your project to help you achieve quality and cost-efficiency.

4. Simplify Designs to Reduce Complexity

Optimizing window designs can significantly reduce production complexity and costs. You can communicate closely with window company to streamline unnecessary design elements, making custom offer windows easier and more cost-effective.

-

💡

Tip: Simple shapes and standard sizes are easier and faster to manufacture, resulting in lower costs. For projects with tight budgets, PA Window's design team can provide practical and efficient solutions without sacrificing aesthetics or functionality.

5. Plan and Order in Advance

Advance planning for custom window orders helps avoid the additional costs associated with rush production or expedited shipping. PA Window’s production process supports flexible scheduling, allowing clients to finalize specifications and quantities early, minimizing costly adjustments later.

6. Solve Tariff and Trade Issues

International trade policies often have a direct impact on the cost of tariff control. After the 2024 US election, the Trump administration is about to take office, and the United States will impose higher tariffs on tariff products imported from China. This trade barrier has affected many importers. It has increased time and financial costs, especially for large-scale projects. The procurement decision has caused considerable pressure.

PA Window has a factory in Indonesia and has rich experience in international trade and tariff handling, which can effectively circumvent these problems for customers. By working with PA Window, you no longer need to spend extra time and money to deal with tariff issues, while ensuring that the product is quickly cleared and delivered on time.

Key Benefits of Custom Windows for Your Projects

We’ve explored why custom windows have higher price and how to make those window costs work within your budget.

Is custom window really worth its value?Is it beneficial for your project?

Let’s have a look!

1. Stand Out as a Wholesaler with Unique Options

Wholesaling windows can be a highly profitable business, but it comes with a common challenge: you’re often limited to offering what manufacturers supply at competitive prices. This means your inventory might lack unique products that set you apart from other wholesalers.

Custom windows can help you change that. If there’s a design frequently requested by your clients or if you identify a demand for specific types of windows that aren’t widely available, wholesale custom window services enable you to fill that gap. By providing window designs that are difficult to source elsewhere, you can cater to underserved markets and establish a competitive advantage.

For window wholesalers, every opportunity to supply unique products to underrepresented markets is invaluable. Custom windows allow you to meet specific demands, satisfy your clients’ individual needs, and offer solutions that other window wholesalers cannot.

2. Meet the Needs of Non-Standard Projects

As a builder, you’re bound to encounter projects that don’t fit the standard mold. Imagine your client commissions a unique home design, and the architect’s plans include windows and doors with dimensions or styles that simply don’t match anything available on the market.

The industry often caters to standard specifications, leaving builders struggling to source the right products for these special cases. Custom windows provide a solution. With custom services, you can order windows tailored specifically to your project’s requirements, whether it’s creating non-standard shapes, adjusting sizes, or even redesigning existing elements.

The flexibility is particularly valuable for contractors handling bespoke properties, renovations of heritage buildings, or other projects that deviate from traditional design practices.

3. Create Visual Impact with Unique Designs

Windows significantly influence a building’s overall aesthetic. If your goal is to create a standout design, relying on off-the-shelf options might not achieve the impact you’re looking for. Pre-made windows often lack the distinctiveness needed to set a project apart.

Custom windows allow you to unleash your creativity and design something that makes your projects truly exceptional. Whether you’re working on a modern commercial space or a bespoke residential property, custom windows enable you to craft visuals that defy standards and exceed client expectations.

4. Elevate Customer Satisfaction

Even if custom windows aren’t being used for a high-end luxury home, just the mention of “custom windows” can leave a lasting impression on clients.

Clients appreciate knowing that their windows were specifically crafted for their property, regardless of the materials or design complexity. This sense of exclusivity can make your service stand out, enhancing client satisfaction and fostering loyalty.

Satisfied customers are more likely to return for future projects, recommend your services to others, and contribute to building a strong reputation for your business. Custom windows may only be one part of the larger picture, but they play a significant role in enhancing the overall client experience.

5. Combination of Customized Services and Efficient delivery

Whether you are a designer, architect or contractor, you need to meet the unique needs of your clients while ensuring that the budget, time and quality of the project are not compromised. You can choose the service of custom standard windows. The advantage of custom standard windows is that it combines the flexibility of personalized customization with the efficiency of mass production, helping you to easily cope with diverse project needs.

By working with the best custom window suppliers, you can not only provide customers with tailor-made window designs, but also enjoy the following key advantages:

- ✔ Wholesale prices: When ordering custom windows in large quantities, the preferential prices provided by suppliers allow you to better control costs while maintaining profit margins.

- ✔ On-time delivery: Efficient supply chain management and production lines ensure that you receive products on time without worrying about the project being stalled due to window delays.

- ✔ Flexible service: Under the premise of ensuring quality, the size, style and function of the windows can be customized according to project needs, helping you to provide customers with more competitive solutions.

How to Get Custom Windows?

When sourcing custom windows that meet the specific needs of your project without breaking your budget, choosing the right partner is critical. For professionals seeking reliability, quality, and efficiency, PA Window is one of the best window supplier choices – trusted by contractors, designers, and developers around the world.

With over 17 years of industry experience, PA Window has established itself as one of the top aluminum window manufacturers in China. As a leading window company, PA focuses on providing tailor-made solutions for large projects, including hotels, apartments, schools, and villas. The PA team’s expertise ensures you get wholesale pricing, timely delivery, and products designed to enhance the value of your project.

What Makes PA Window Different than Other Window Companies?

Proven expertise: PA Window is recognized as a top 10 window manufacturer for its ability to meet the high standards of B2B clients, including developers, contractors, builders, and wholesalers, among others.

Global reach and efficient delivery: With manufacturing facilities in Indonesia and a strong international supply chain, on-time delivery and seamless logistics are ensured to help you avoid costly delays.

Customized Solutions for Every Project: Whether you need large-format windows for a commercial property or unique designs for a high-end residence, PA Window offers best-in-class customization options that fit your budget and vision.

Whole-House Customization and One-Stop Solutions:

PA Window goes beyond windows. PA provide whole-house customization solutions, covering products like aluminum windows & doors, kitchen cabinets, bathroom vanities, interior doors, wall panels, and more. From initial consultations to on-site measurements, professional installation, and after-sales service, PA offer a complete one-stop solution tailored to your project needs.

Contact PA Window today to experience the difference of working with one of the best window manufacturers in China!

FAQs

Custom windows typically cost between $500 and $2,500 per window, depending on size, material, design complexity, and additional features. Bulk orders often qualify for wholesale pricing, reducing overall costs.

Custom windows are more costly due to their tailored designs, specialized materials, and additional labor required for manufacturing. These factors ensure the windows meet specific project requirements and offer unique functionality and aesthetics.

Yes, wholesale discounts are available for large orders. Reliable suppliers like PA Window offer competitive pricing for contractors and window wholesalers handling large-scale projects.

Custom windows typically take 6–10 weeks to manufacture and deliver, depending on the complexity of the order and the supplier’s production capacity. Trusted suppliers like PA Window ensure timely delivery to keep projects on schedule.

Yes, custom windows are ideal for projects with unique specifications or designs. They can be tailored to specific dimensions, styles, and functional requirements.